Investigation of paper-based electronics continues to advance, showing exciting signs of progress.

Tsukuba, Japan — Imagine folding up a paper-thin computer tablet like a newspaper. It sounds like something out of a science fiction movie, but such flexible electronics are moving closer to reality, according to a review in the journal Science and Technology of Advanced Materials.

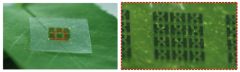

Paper that is transparent and conducts electricity could have widespread applications, including foldable computers, transparent touch screens, and even digital camouflage clothing.

“With widespread and intensive efforts, low-cost and light-weight ‘green’ electronics fabricated on transparent nano paper substrate will provide new technologies impacting our daily life,” state the review paper authors from Nanyang Technological University in Singapore.

Cellulose, the building block of paper taken from plants, is an exciting alternative to the plastic, glass and silicon that currently make up most electronic devices, including computers and mobile phones. Cellulose is renewable, biodegradable, strong, and lightweight. For the past 30 years, scientists have considered ways to combine these properties with electronics. Significant progress has been made in the past decade to manipulate the smallest plant fibers, called “nanocellulose”, for use in electronics.

For example, researchers at Nanyang Technological University have made “nanopaper” out of nanocellulose and silver nanowires. It still conducted electricity after being folded in half 500 times. Some nanopapers have reached 90% transparency, while others are in the 80% range, similar to plastic. But, better than plastic, nanopapers degrade quickly. After metal electrodes are removed, nanopaper can be buried in soil and will fully degrade within a month. Researchers are still working on how to treat nanopapers that contain non-biodegradable materials, such as epoxy, to maintain their recyclability.

Many challenges remain before nanocellulose electronics become widespread. Currently, it is more expensive to produce pure nanopaper than glass or plastic. Cheaper preparation and fabrication methods are needed. Ideally, a common high-speed printing process used in electronic manufacturing called “roll to roll” can be adapted for nanocellulose. Also, the hydrophilic properties of cellulose make the items easy to degrade; this is desirable when it is time to dispose of them, but not during their operational life. The authors are optimistic that if these issues can be addressed, a wide range of electronics could soon be built from plants.